Get Free Consultation!

We are ready to answer right now! Sign up for a free consultation.

I consent to the processing of personal data and agree with the user agreement and privacy policy

Looking for a clear guide to AC compressor control valve replacement? This article explains when and how to replace the valve, why the compressor often needs removal, and the safety steps you should never skip—especially on hybrid vehicles. Brought to you by Qirun Auto Parts Co., Ltd. — a specialist in car AC compressor control valves with 15+ years of export experience and a 1-month quality warranty.

Explore technical resources and product options at our sites: qirunauto.com | qrcontrolvalve.com.

If these signs appear, a control valve inspection is recommended. For background reading from a community Q&A scenario, see this 2CarPros discussion.

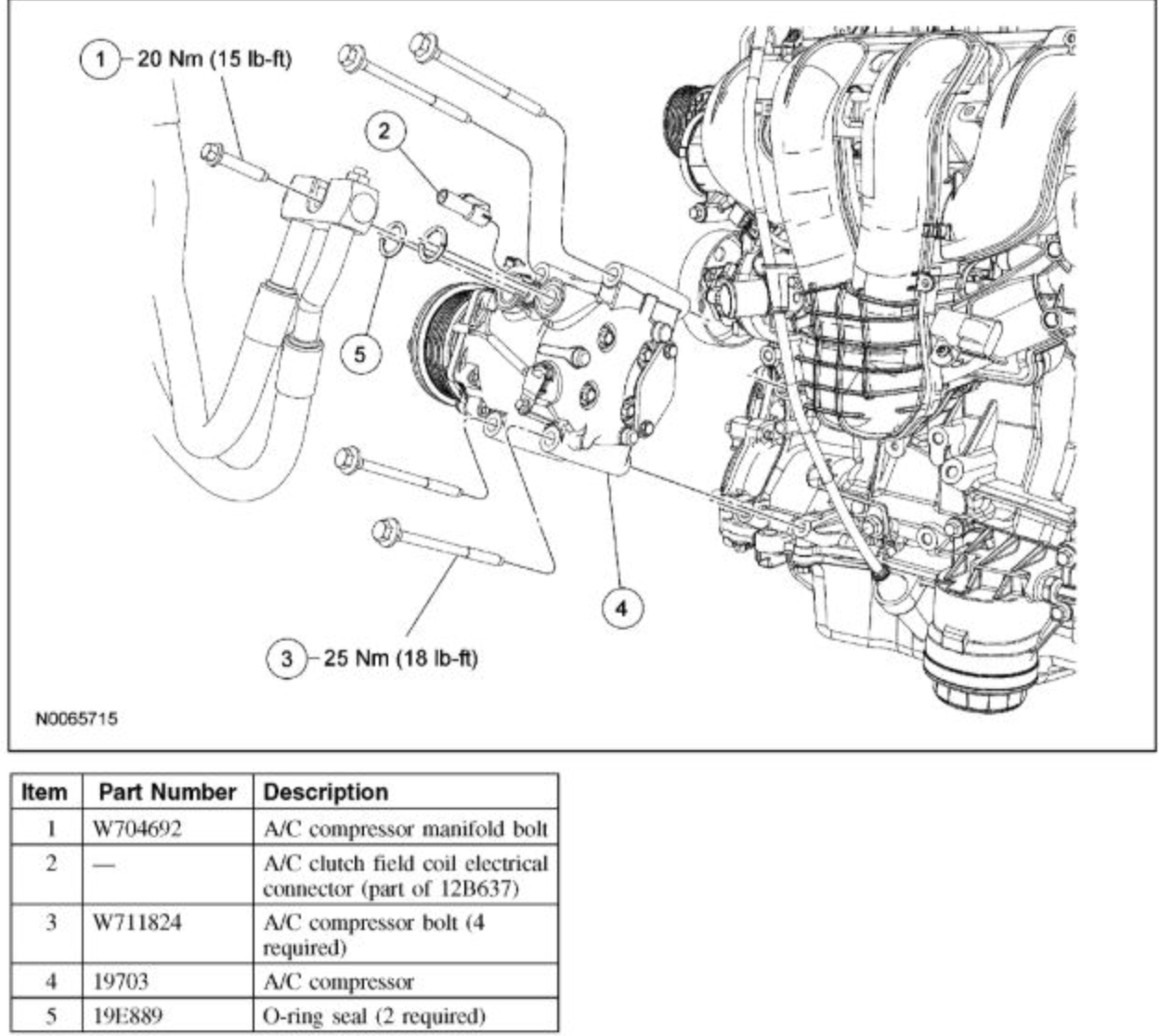

In many vehicles, yes. The control valve is mounted in the rear housing of the compressor. Proper access and a clean work area typically require compressor removal. Additionally, the system must be professionally evacuated before any compressor-side work to prevent refrigerant release and moisture contamination.

Always evacuate refrigerant with certified equipment. On hybrid vehicles, follow high-voltage disable procedures and PPE requirements. If you are not trained, use a certified A/C technician.

Note: A forum expert case (similar to a 2008 Ford Escape Hybrid) confirms that removing the compressor and discharging refrigerant is typically required for control valve replacement. Reference: 2CarPros Q&A.

Need bulk supply of AC compressor control valves with consistent quality and fast export support? Qirun Auto Parts Co., Ltd. delivers:

Address: 佛山市南海区桂城街道夏南二上元南工业区

Phone (WhatsApp/WeChat): +86-13690143493

Email: a13690143493@gmail.com

Websites: qirunauto.com | qrcontrolvalve.com

Usually no. Access, cleanliness, and correct seal installation typically require compressor removal. The system must be evacuated first.

Yes. A certified recovery machine must evacuate the refrigerant before opening the system.

Follow OEM high-voltage disable procedures and wear proper PPE. If unsure, hire a certified technician.

Replace the drier/accumulator and O-rings. Flush lines and condenser (if design permits) when contamination is suspected.

Charge by weight, ensure fans and condenser are efficient, use the correct oil type and volume, and verify the control signal to the valve.